Resume

New materials and coatings

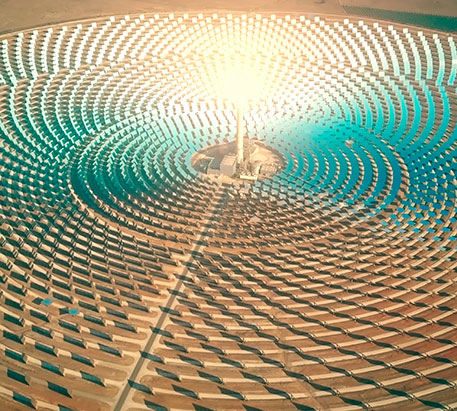

Over the past few years there has been a great deal of interest in concentrated solar power (CSP) plants, mainly due to their proven thermal energy storage (TES) system.

In addition, CSP plants can contribute to reducing CO2 emissions, a potential recognized by the EU. However, additional efforts are still needed to make CSP an economically viable technology to gain an advantage over other renewable and fossil fuel energies.

One of the main strategies for this purpose is to increase the plant operating temperature to achieve higher efficiencies. This improvement would also allow the integration of the Brayton power cycle using supercritical CO2 (s-CO2), with higher power conversion efficiency than the current steam cycle (Rankine cycle).

More aggressive operating conditions imply higher requirements for plant construction materials. Current molten nitrates used as a heat transfer fluids (HTF) and TES are limited to 580°C which avoids an efficiency increase. Therefore, to achieve an increase in the efficiency

of solar thermal technology, it is necessary to find more efficient materials that allow and resist the new operating conditions, but without increasing costs.

Thus COCO focuses on novel advanced materials and coatings with long-term performance for two key components:

Heat transfer fluids and storage materials

New molten salt mixtures with a higher thermal stability point (up to 700ºC) are required to increase plant efficiency. In parallel, COCO focuses on the behavior of protective coatings deposited on austenitic steel that will resist corrosion caused by the newly developed salt mixtures.

The durability of these coatings will be investigated with the salt mixtures at 700ºC both in static and dynamic conditions at laboratory scale and in pilot scale.

s-CO2 energy cycle

s-CO2 is considered as a working fluid in the new Brayton power cycles due to its very low economic value. However, the corrosion resistance of candidate structural materials in this oxidizing environment is more than necessary to be investigated.

COCO focuses on studying the corrosion behaviour of several slurries aluminide and HVOF coatings in s-CO2 atmosphere, under both atmospheric and high pressure after long term exposure.